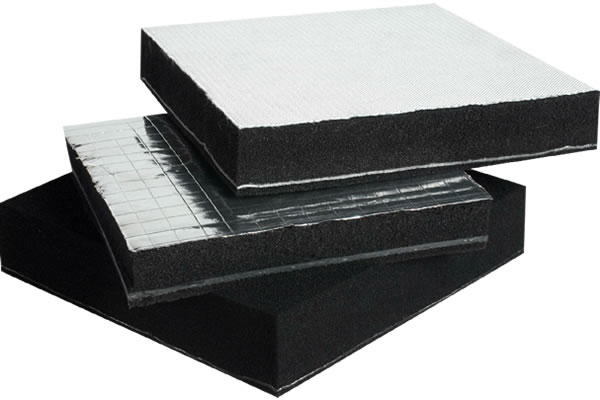

PROCELL is an open-celled, flexible polyurethane acoustical foam impregnated with high amount of flame retardants and polymeric bonding materials, offering solutions for non-flammable performance and sound attenuation features.

PROCELL emphasizes it’s following foremost characteristics:

- Flameproof

- Density

- Open-celled structure

- Thickness

- Surface variations

Physical Properties

| Specification | Value | Value | Value |

|---|---|---|---|

| Density | ≥70 Kg/m3 | 90-100 Kg/m3 | 100-120 Kg/m3 |

| Thickness | From 5 mm to 55 mm in block F | From 5 mm to 55 mm in block F | From 5 mm to 55 mm in block F |

| Tensile Strength | >75 kpA | >75 kpA | >70 kpA |

| Tension Capacity | 130% | 130% | 130% |

| Thermal Resistance ( short usage ) | -30 °C – +130 °C | -30 °C – +130 °C | -30 °C – +130 °C |

| Thermal Resistance ( regular usage ) | -30 °C – +100 °C | -30 °C – +100 °C | -30 °C – +100 °C |

Fire Performance

| Method | TS EN ISO 13501-1+A1 | BS 476 Part 6&7 | NF P 92-501 |

|---|---|---|---|

| Fire Classification | C-s2-d0 | Class 0 | M1 |

Sound Absorption Values

PROCELL Flameproof Acoustical Plain Foam 70 density, 50 mm.

Rolls

Rolls Die cut parts

Die cut parts Kits

Kits